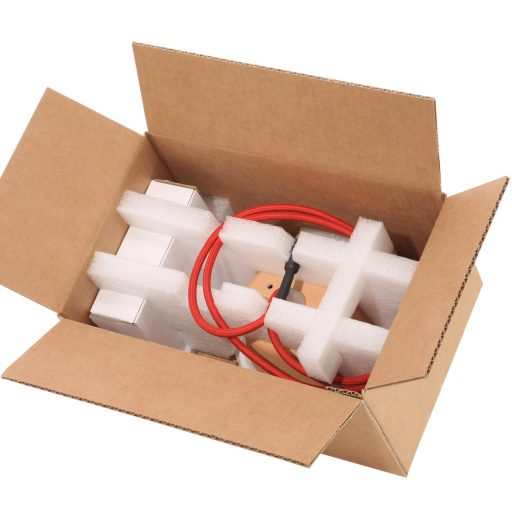

Packaging in expanded polyethylene and expanded materials (PU, EPS, PPL)

Expanded polyethylene is the name polyethylene acquires when it is transformed through an extrusion process.

Expanded polyethylene is characterized by its closed cell structure which makes it impermeable to water, resilient and resistant to compression.

These characteristics make expanded polyethylene a high performance shockproof material particularly suitable for applications in the protective packaging sector and particularly suitable for protecting and preserving industrial products or delicate surfaces from scratches and bumps.

Available as raw material in sheets or reels in various thicknesses and densities, expanded polyethylene can be easily glued or coupled with other materials. In our production plants in Italy and Poland we process the equivalent of 60,000 m3 of expanded polyethylene per year.

DELES Lab

ISTA (International Safe Transit Association) certified laboratory since 2005 dedicated to pack engineering

Our commitment to respect the environment

- Recycling of production waste and re-entry into the production cycle

- Use of low densities

- Reduction in the amount of material used in packaging design

- Expanded polyethylene is recyclable with plastic materials.