One source, multiple values

It allows to satisfy in a single supply all the activities and solutions for the care of the product during its entire life cycle, through the transversal integration of specific skills.

TAILOR-MADE

SOLUTIONS

Customization based on real business needs.

OPERATIONAL

EFFICIENCY

Optimize each stage for continuous improvement.

COSTS

OPTIMIZATION

A net advantage both in economic and operational terms.

SIMPLIFICATION

OF PROCESSES

We rationalize packaging codes against proliferation and obsolescence.

HIGH QUALITY

MATERIALS

Our packaging is made with eco-sustainable and high quality materials.

Vision of the entire flow to be able to manage it strategically, efficiently and effectively.

Benefits Continuous improvement can be seen!

Less orders

Fewer bills

Focus on the core business

Increased operational efficiency in 3 years

Stock reduction

Space optimization

Transport optimization

Efficiency of logistics in 3 years

Flow optimization

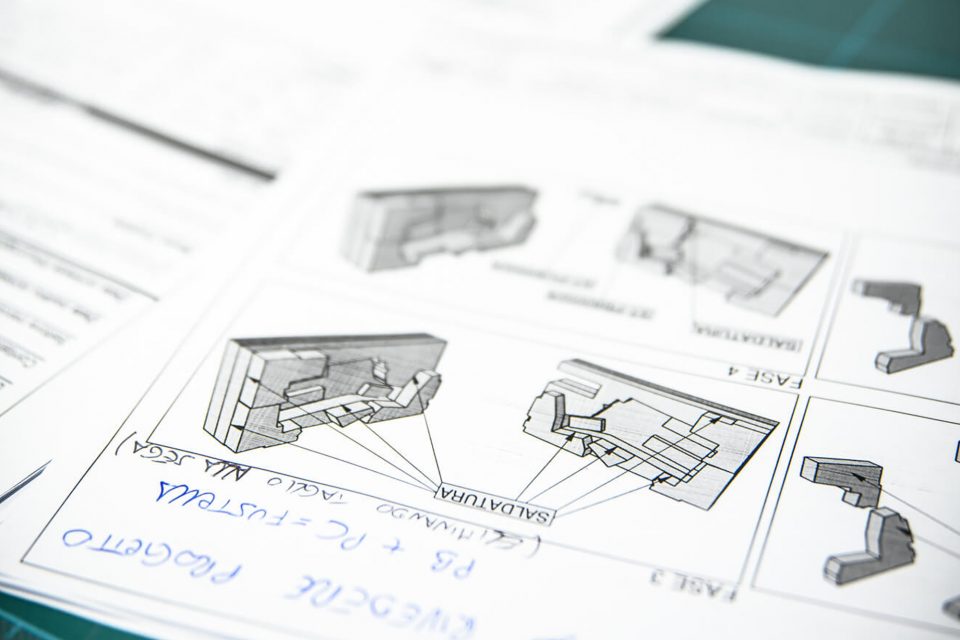

Pack re-engineering

Eco-sustainable materials

GREEN impact improvement

Automation

Flexibility

Strategic vision

Innovation projects every year

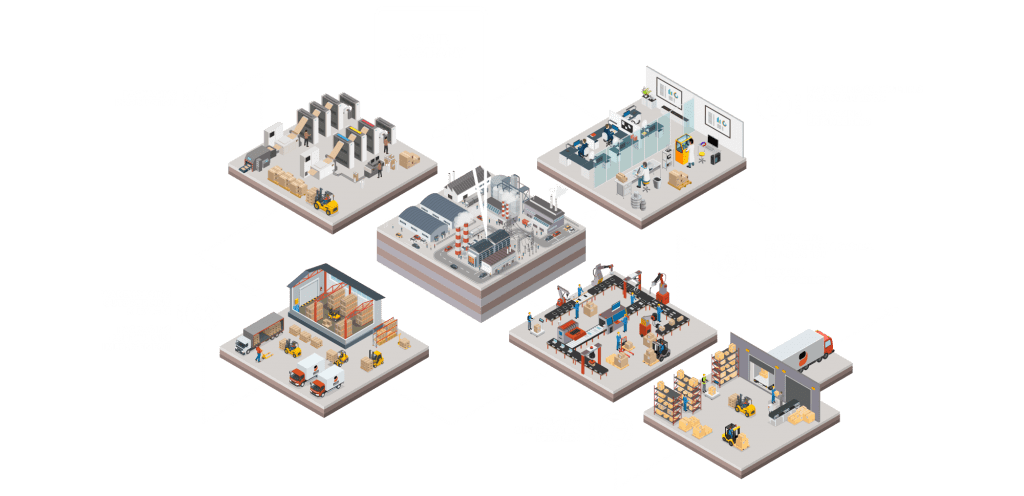

OPERATIONAL FLOW The path to excellence

From packaging design, material sourcing, packaging production, contract packing and end-of-line automation, to the supply of outsourced logistics services and after-sales services.